Lift Maintenance Repair: Vital Solutions for Optimal Lift Performance

Lift Maintenance Repair: Vital Solutions for Optimal Lift Performance

Blog Article

Opening the Tricks to Reliable Lift Services: Specialist Insights Exposed

In the world of lift repair service and maintenance, revealing the methodologies that lead to efficient and reliable service belongs to deciphering an intricate problem. Professional insights work as the directing light through the maze of difficulties faced by upkeep specialists in the vertical transport sector. By diving into the midsts of positive techniques, troubleshooting methods, and the continuous search of ability enhancement, the course to raising maintenance standards reveals itself. As we start this journey to demystify the keys behind streamlined lift repairs, a globe of opportunities arises, assuring a future where downtime is lessened, security is focused on, and operational quality ends up being the norm.

Typical Lift Repair Difficulties

One more prevalent difficulty in lift repair work is the lack of proper upkeep documents. Without precise maintenance records, repair specialists may struggle to detect concerns properly or prepare for potential problems. This can lead to longer repair work times and enhanced costs as specialists function to fix issues without historic information to direct them.

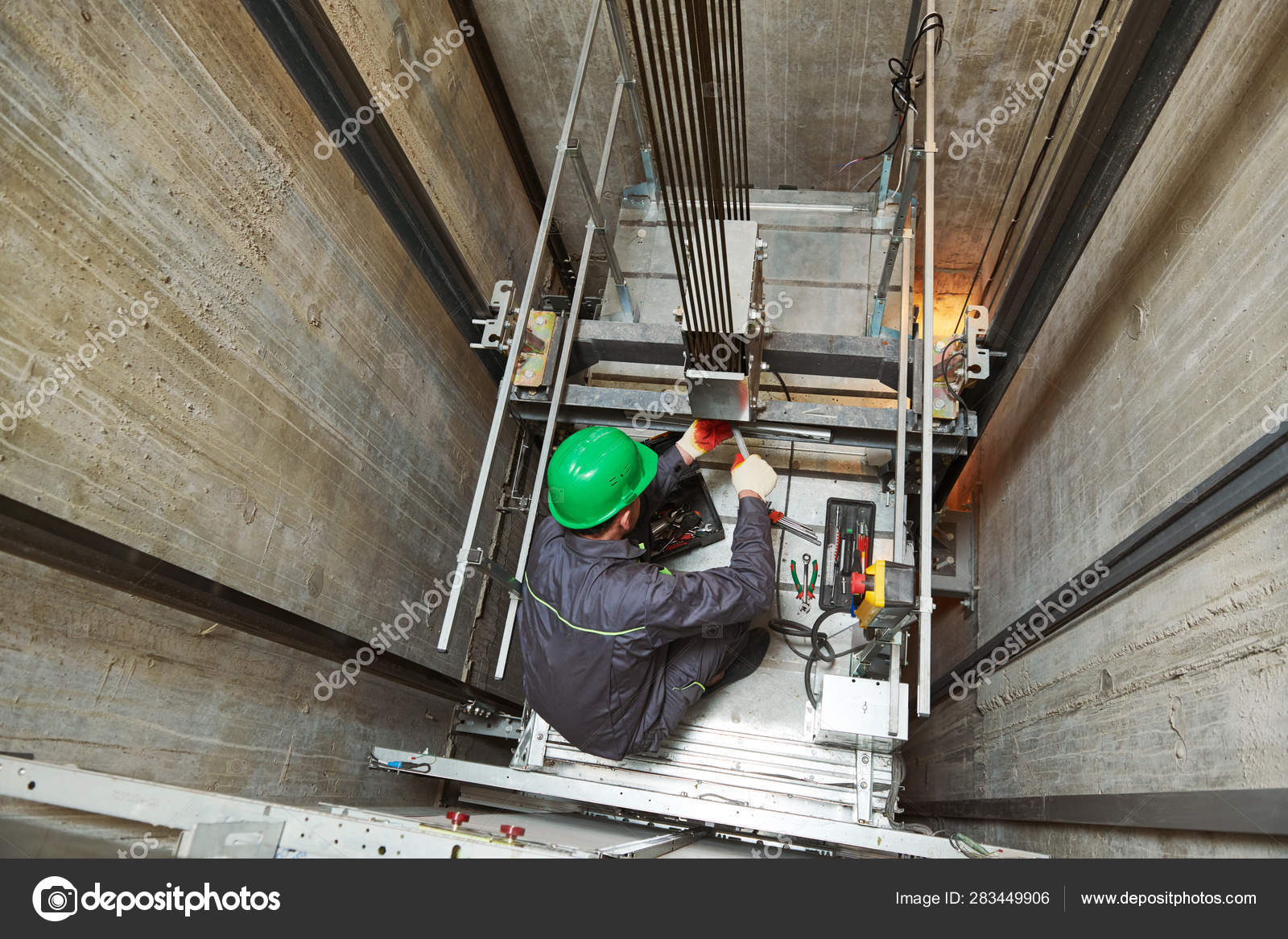

Additionally, accessibility concerns within lift shafts can present significant obstacles throughout repair work. Minimal area, awkward angles, and intricate machinery can make it difficult for technicians to reach the essential elements for repair job, prolonging the total repair service process - Lift Maintenance Repair. By attending to these common obstacles proactively, lift repair work specialists can improve functional efficiency and make certain the smooth functioning of upright transportation systems

Proactive Upkeep Techniques

Applying positive upkeep strategies is vital for guaranteeing the long life and optimal performance of lift systems. By taking on a proactive technique to upkeep, building managers and lift upkeep teams can resolve prospective concerns prior to they escalate right into pricey repairs or downtime. One reliable approach is to develop a normal maintenance routine that consists of comprehensive assessments, lubrication of relocating components, and testing of security functions.

In addition, purchasing training programs for upkeep team can boost their abilities in determining prospective problems and executing preventative upkeep jobs properly - Lift Maintenance Repair. By encouraging upkeep groups with the understanding and tools needed to proactively maintain lift systems, building proprietors can decrease disturbances, expand the life expectancy of their lifts, and make sure a trustworthy and risk-free vertical transportation experience for residents

Fixing Techniques

Efficient fixing techniques are necessary for promptly determining and settling problems with lift systems to reduce downtime and make certain optimum performance. One efficient strategy is to start with a thorough visual examination of the lift parts, checking for any noticeable indications of wear, misalignment, or damages.

Enhancing Repair Service Skills

Enhancing efficiency in lift system repairs is an essential facet of making sure optimum capability and minimizing operational interruptions. Elevator professionals must continuously function on honing their repair work abilities to fulfill the needs of modern lift systems.

Moreover, remaining upgraded with the current improvements in lift modern technology is critical for professionals looking to improve their repair service abilities. This entails proactively inquiring concerning brand-new components, software updates, and maintenance methods to successfully identify and remedy problems. By spending time and initiative right into continual understanding and practical experience, elevator technicians can considerably increase their repair work proficiencies and contribute to the effective functioning of lift systems.

Elevating Maintenance Standards

Boosting maintenance standards in lift systems is paramount for making certain long term functional effectiveness and the original source security. Regular maintenance not just improves the performance of lift systems but also decreases the threat of unforeseen break downs and ensures the safety and security of customers. By sticking to strict upkeep methods, lift owners and operators can dramatically minimize the possibility of costly fixings and downtime.

Carrying out an extensive maintenance timetable that includes normal assessments, lubrication of moving components, and positive substitute of used components is critical. Using advanced modern technologies like IoT sensors and anticipating maintenance software program can assist in keeping track of the lift's problem in real-time, enabling prompt interventions prior to issues intensify. Additionally, supplying continuous training for upkeep staff on the current industry requirements and ideal methods is essential for maintaining upkeep excellence.

Additionally, promoting a society of accountability and attention to information amongst upkeep groups can even more raise upkeep criteria. Urging open communication channels for reporting and addressing upkeep issues immediately can assist in maintaining a high level of lift system reliability. Ultimately, by prioritizing and elevating upkeep standards, lift systems can run successfully and safely for an extended duration.

Conclusion

To conclude, reliable lift repair services require aggressive upkeep techniques, repairing methods, and boosted repair service abilities. By elevating and resolving common difficulties upkeep requirements, maintenance professionals can effectively ensure the smooth procedure of lifts - Lift Maintenance Repair. Carrying out these professional insights can cause improved more information performance, reduced downtime, and raised security for both travelers and devices

In the world of lift repair service and maintenance, uncovering the approaches that lead to effective and efficient solution is akin to deciphering a complicated challenge.An additional widespread useful source challenge in lift repair work is the absence of correct maintenance documents. By taking on a proactive method to maintenance, building supervisors and lift upkeep groups can address prospective issues before they intensify into costly repair work or downtime.In conclusion, efficient lift fixings call for positive upkeep methods, troubleshooting methods, and improved fixing abilities. By dealing with usual challenges and elevating maintenance criteria, upkeep experts can properly ensure the smooth operation of lifts.

Report this page